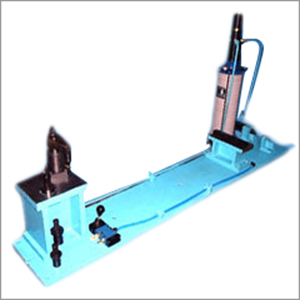

Drill Jigs

Product Details:

- Life Span Up to 5 years under standard use

- Die Head High-precision steel body, hardened finish

- Working Process Guided drilling operations for accuracy

- Shaping Mode Machining/Fabrication

- Material Alloy Steel / Hardened Tool Steel

- Application Jig boring, industrial drilling, mass production

- Hardness 58-62 HRC

- Click to view more

X

Drill Jigs Price And Quantity

- 1 Piece

- Precision locator pin and bushing

- Drilling machines, vertical turbines

- Black oxide, silver

- CNC machined for close tolerances

- Anti-corrosive treated

- Interchangeable, fixed

- Varies by model (0.5-10 kg approx.)

- Suitable for workshop and factory environments

- Heat treated, rust resistant coated

- Fine ground finish

- Custom and standard options on request

Drill Jigs Product Specifications

- Alloy Steel / Hardened Tool Steel

- Machining/Fabrication

- Guided drilling operations for accuracy

- 0.01 mm

- Up to 5 years under standard use

- Jig boring, industrial drilling, mass production

- High-precision steel body, hardened finish

- 58-62 HRC

- Precision locator pin and bushing

- Drilling machines, vertical turbines

- Black oxide, silver

- CNC machined for close tolerances

- Anti-corrosive treated

- Interchangeable, fixed

- Varies by model (0.5-10 kg approx.)

- Suitable for workshop and factory environments

- Heat treated, rust resistant coated

- Fine ground finish

- Custom and standard options on request

Drill Jigs Trade Information

- Telegraphic Transfer (T/T)

- Wooden and plastic packaging

- All India

Product Description

With consistent focus on the current market, we bring forth a unique range of Drill Jigs. The offered jig is used for driiling of component from a certain distance accurately. It has main use of drilling small components as well as big compounds in metallurgical industry. This is obtainable in various sizes, shapes and specifications as per client's requirement. The offered products are specially designed to accelerate repetitive holes on multiple interchangeable parts. To provide the best range, we check this Drill Jigs on efficiency and working parameters.

Precision-engineered for Accuracy

Each drill jig is CNC machined to achieve close tolerances of 0.01 mm and hardness levels between 58-62 HRC. This high level of engineering ensures reliable guidance for drills, boosting accuracy and repeatability in workshop and mass production settings.

Versatile Surface Treatments

Surface treatments such as heat treatment and fine ground finishes, along with anti-corrosive coatings, protect the jig from rust and wear. These features contribute to a longer lifespan and enhanced performance, even in challenging industrial environments.

Flexible Clamping & Bushing Systems

Choose between interchangeable or fixed bushings and benefit from precision locator pins and bushings for secure clamping. These features facilitate fast setup and consistent alignment, allowing users to maintain operational efficiency across various machines.

FAQs of Drill Jigs:

Q: How do drill jigs with fine ground finishes and heat treatment improve accuracy during drilling operations?

A: Drill jigs featuring fine ground finishes and heat treatment maintain precise dimensions and hardness, which helps guide drills accurately and minimizes deviation, resulting in consistently high-quality drilled holes.Q: What types of machines are compatible with these drill jigs?

A: These drill jigs are suitable for a wide range of drilling machines, vertical turbines, and can be used with die heads for jig boring and mass production in workshops and factory environments.Q: When should I opt for custom-sized jigs versus standard sizes?

A: Custom-sized jigs are recommended when your application requires specific dimensions, hole spacing, or unique setups not covered by standard options, ensuring optimal fit and performance for special projects.Q: Where can these drill jigs be used for best results?

A: These drill jigs deliver optimal performance in industrial workshops, factories, and other settings where accurate, repeatable drilling is necessary for mass production or high-precision operations.Q: What is the benefit of the interchangeable bushing system on these jigs?

A: Interchangeable bushings allow quick replacement or adaptation to different drill sizes and operations, reducing downtime and extending the utility and lifecycle of the jig.Q: How does the rust-resistant coating and anti-corrosive treatment protect the drill jig?

A: The rust-resistant coating and anti-corrosive treatments shield the jig from oxidation and environmental factors, safeguarding its mechanical properties and ensuring reliable performance over time.Q: What is the expected lifespan of the drill jigs under standard factory conditions?

A: With robust manufacturing techniques and extensive surface treatments, these jigs typically last up to 5 years in standard workshop or factory environments when used and maintained properly.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email