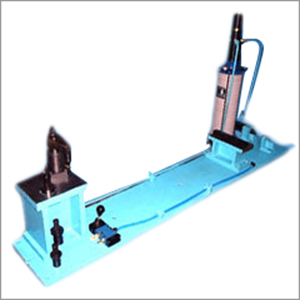

Assembly Fixtures

Product Details:

- Working Process Assembly and holding of workpieces

- Life Span 5 Years under recommended usage

- Die Head Precision machined, replaceable type

- Shaping Mode Fixture-based location and retention

- Material High-quality Tool Steel

- Application Automotive, Electronics, Machine Manufacturing

- Hardness Up to 58 HRC

- Click to view more

X

Assembly Fixtures Price And Quantity

- 1 Piece

- Bolt-on/Quick-release

- Low, periodic lubrication required

- Rustproof coating

- Up to 120°C

- High

- Up to 350 kg

- Between 5-30 kg (depending on size/model)

- Bench/Modular mounting compatible

- Custom and standard designs

- Smooth ground

- Manual/Automatic options available

Assembly Fixtures Product Specifications

- Automotive, Electronics, Machine Manufacturing

- Fixture-based location and retention

- 5 Years under recommended usage

- Precision machined, replaceable type

- Up to 58 HRC

- High-quality Tool Steel

- Assembly and holding of workpieces

- 0.01 mm

- Bolt-on/Quick-release

- Low, periodic lubrication required

- Rustproof coating

- Up to 120°C

- High

- Up to 350 kg

- Between 5-30 kg (depending on size/model)

- Bench/Modular mounting compatible

- Custom and standard designs

- Smooth ground

- Manual/Automatic options available

Assembly Fixtures Trade Information

- Telegraphic Transfer (T/T)

- Wooden and plastic packaging

- All India

Product Description

Based on the skills of our adept professionals and skilled workers, we are offering a commendable assortment of Assembly Fixtures. Fast boosting speed, excellent performance and high oil storage capacity are some of the prominent qualities of the range that make it highly famous in the market. Additionally, we also offer customized version of Assembly Fixtures as per the specifications detailed by the customers. Our huge expertise and skills in the respective domain enables the company to understand the requirement of the clients and fulfil them accordingly.

Superior Surface Protection & Longevity

Each assembly fixture is treated with a rustproof coating and precision ground finish, providing excellent corrosion resistance. This ensures longevity, even in challenging production environments. Coupled with a lifespan of up to five years under recommended usage, the fixtures withstand frequent use without compromise in performance.

Versatile Mounting and Clamping Options

Our fixtures support both bench and modular mounting, allowing seamless integration into diverse assembly lines. With manual and automatic clamping mechanisms available, users can easily select the appropriate solution for their operational needs, enhancing workflow flexibility and efficiency.

Precision and Reliability for Demanding Industries

Whether for automotive, electronic, or machine manufacturing, these fixtures guarantee accurate location and retention of workpieces with a working tolerance of 0.01 mm. The robust, precision-machined die heads are easily replaceable, minimizing downtime and maintaining consistent quality in high-volume production settings.

FAQs of Assembly Fixtures:

Q: How do the assembly fixtures provide protection against rust and corrosion?

A: The fixtures undergo a specialized rustproof surface treatment and are finished with a smooth, ground surface. This process ensures high corrosion resistance, making them suitable for prolonged industrial use.Q: What is the maximum load these fixtures can support during operation?

A: The assembly fixtures are engineered to handle loads of up to 350 kg, making them suitable for heavy-duty applications across various industries.Q: When should maintenance be performed on these assembly fixtures?

A: Maintenance is minimal, requiring only periodic lubrication in accordance with recommended guidelines. This helps prolong the fixtures lifespan and ensure reliable performance.Q: Where can these fixtures be installed or mounted?

A: They are compatible with both bench and modular mounting systems, offering flexibility for integration into different assembly setups within automotive, electronics, or machine manufacturing environments.Q: What are the benefits of choosing custom designs for assembly fixtures?

A: Custom-designed fixtures ensure precise alignment and retention for unique or complex workpieces, optimizing assembly efficiency and maintaining tight tolerances.Q: How does the quick-release or bolt-on connection enhance fixture usability?

A: These connection types enable fast, secure installation and removal, minimizing setup time and facilitating quick changes on production lines.Q: What processes are these fixtures designed for, and how do they improve productivity?

A: Assembly fixtures are specifically designed for holding and positioning workpieces during assembly operations, enhancing accuracy, repeatability, and overall productivity within the working process.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email